We can respond to demands not only for springs, screws and mesh, but for applications such as medical, aircraft and food handling as well. Please contact us, and let's discuss what we can do for you.

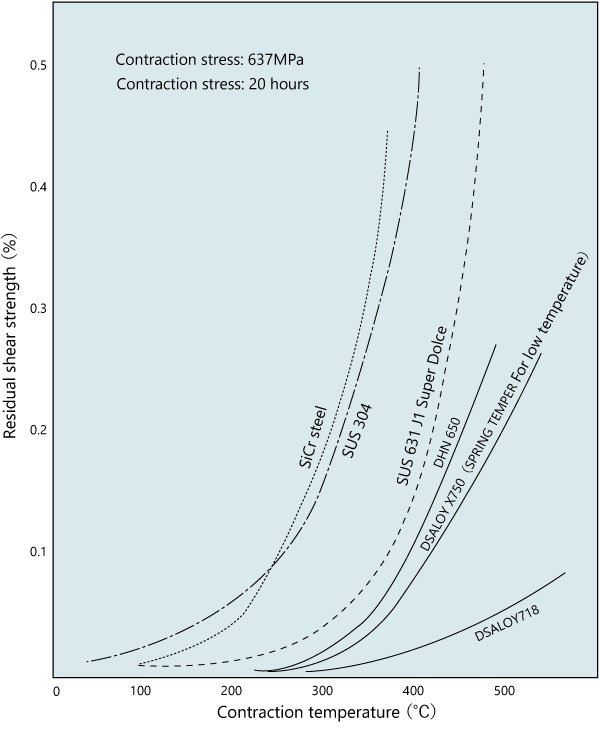

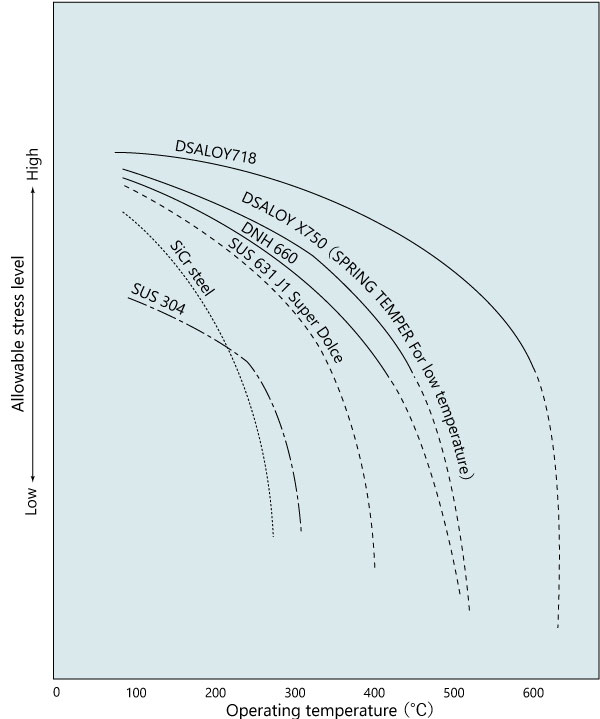

Heat-resistant material (Super alloy)

We offer heat and corrosion resistant materials that can be used at higher temperature ranges than conventional SUS steel wire.

| Steel grade | C | Si | Mn | P | S | Ni | Fe |

| DSA718 | ≦0.08 | ≦0.35 | ≦0.35 | ≦0.015 | ≦0.015 | 50.00〜55.00*1 | Residue |

| DSA750 | ≦0.08 | ≦0.50 | ≦1.00 | - | ≦0.010 | ≧70.00 | 5.00〜9.00 |

| Steel grade | S | Ni | Fe |

| DSA718 | ≦0.015 | 50.00〜55.00*1 | Residue |

| DSA750 | ≦0.010 | ≧70.00 | 5.00〜9.00 |

- *1

- Ni+Co

| Steel grade | Mo | Cu | Cr | AI | Ti | Nb+Ta | B |

| DSA718 | 2.80〜3.30 | ≦0.30 | 17.00〜21.00 | 0.20〜0.80 | 0.65〜1.15 | 4.75〜5.50 | ≦0.006 |

| DSA750 | - | ≦0.50 | 14.00〜17.00 | 0.40〜1.00 | 2.25〜2.75 | 0.70〜1.20 |

| Steel grade | Ti | Nb+Ta | B |

| DSA718 | 0.65〜1.15 | 4.75〜5.50 | ≦0.006 |

| DSA750 | 2.25〜2.75 | 0.70〜1.20 |

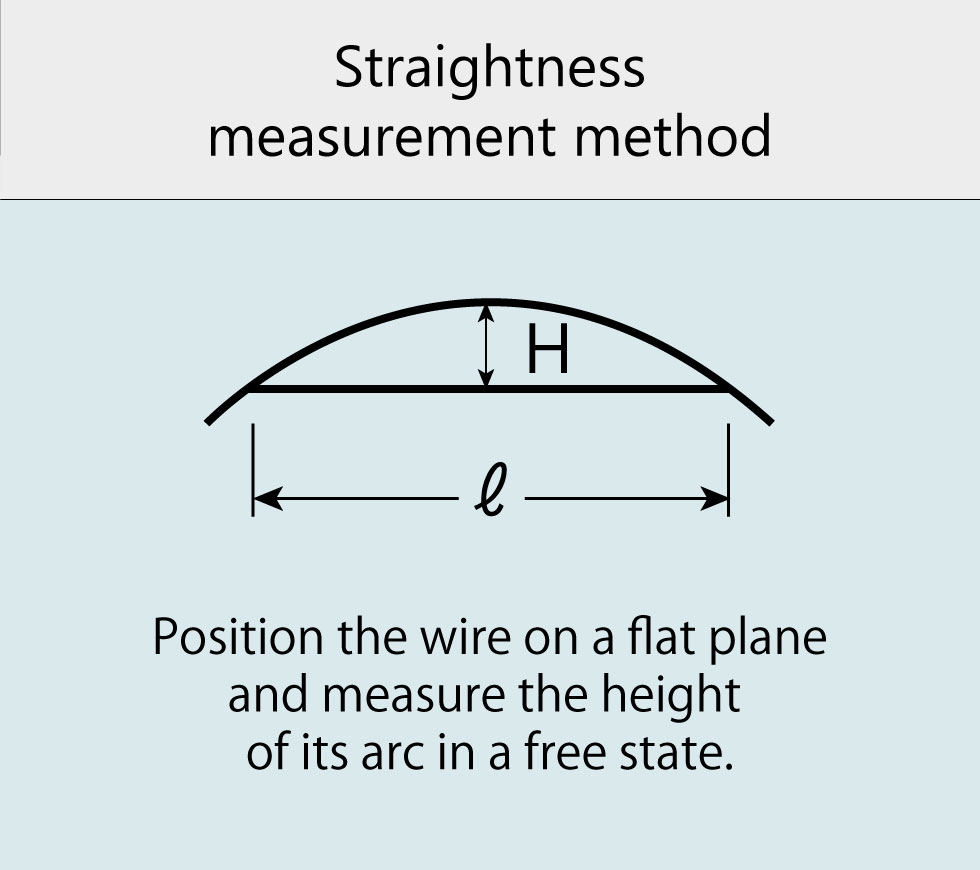

Straightened stainless steel wire

When used in torsion springs or for formation processing, materials with a high degree of straightness offer improvements in work efficiency, quality and consistency. Our straightened stainless steel wire has excellent surface gloss and straightness, and heightens work efficiency as it does not need to be re-bent.

| Wire diameter [mm] |

Tensile strength [N/mm2] |

Straightness [mm] |

||

| SUS304-WPAS | SUS304-WPBS | Arc height (H) | Sample length (ℓ) | |

| 0.20 0.23 |

1860〜2060 1770〜2010 |

2060〜2400 2010〜2300 |

Less than 2 | 100 |

| 0.26 0.29 0.32 0.35 0.40 0.45 |

1770〜2010 1720〜2010 1720〜2010 1720〜2010 1720〜2010 1720〜1960 |

2010〜2300 2010〜2300 2010〜2300 2010〜2300 2010〜2300 1960〜2260 |

Less than 5 | 200 |

| 0.50 0.55 0.60 0.65 0.70 0.80 0.90 |

1670〜1910 1670〜1910 1670〜1910 1670〜1910 1620〜1910 1570〜1810 1570〜1810 |

1910〜2210 1910〜2210 1910〜2210 1910〜2210 1910〜2210 1810〜2110 1810〜2110 |

Less than 4 | 200 |

| 1.00 1.20 |

1570〜1810 1470〜1720 |

1810〜2110 1720〜2010 |

||

- Note:

- For wire diameter in the middle, the value will be larger.

- *

- Please inquire about our ability to manufacture other sizes or for more detailed specifications.

Free cutting stainless steel wire

In order to respond to customers' needs for faster and more efficient cutting, we can prepare materials with special components added, taking into consideration machinability, cutting resistance, tool life and other characteristics. The results have led to strong user satisfaction.

| Steel grade (tempering) | Wire diameter [mm] | Tensile strength [N/mm2] |

| SUS303(-BA), (-SP) | 1.05〜12.15 | 590〜740 |

| SUS303Cu(-BA), (-SP) | 1.05〜12.15 | 540〜690 |

| SUS303(-BA), (-SP) | 1.05〜12.15 | 540〜740 |

- Note:

- For wire diameter in the middle, the value will be larger.

- Note 2:

- Austenitic types must not exceed the following permeability µ.

SUS303: µ=1.02 or less

SUS303Cu: µ=1.01 or less - *

- Please inquire about our ability to manufacture other sizes or for more detailed specifications.

Cold finished stainless steel wire

In response to the needs of customers who are diversifying more and more in the high-tech era, we offer special processing on JIS items, as well as various non-JIS austenitic and martensitic materials with special components added. We are fully satisfied that these materials meet all applicable quality requirements, including those for high precision shafts and pins, along with excellent corrosion and abrasion resistance.

| Steel grade (tempering) | Wire diameter [mm] | Tensile strength [N/mm2] |

| SUS304(-BA), SUS304N1(-BA), SUS316(-BA) | 1.05〜9.15 | 540〜740 |

| SUS304(-SP), SUS304N1(-SP), SUS316(-SP) | 1.05〜9.15 | 740〜930 |

| SSS130M | 1.00〜4.20 (more than) | 1960〜2210 |

| 4.20〜6.65 | 1760〜2010 |

- Note:

- For wire diameter in the middle, the value will be larger.

- *

- Please inquire about our ability to manufacture other sizes or for more detailed specifications.

Facile

| Product symbol | Wire diameter [mm] | Tensile strength [N/mm2] |

| Facile | 0.50 | 1900〜2150 |

| 1.00 | 1800〜2050 | |

| 1.50 | 1700〜1950 | |

| 2.00 | 1600〜1850 | |

| 2.50 | 1500〜1750 |

Under a high temperature and high pressure hydrogen atmosphere

- High strength (equivalent to SUS304WPB)

- High toughness and anti-fatigue strength(SUS304WPB, SUS631J1 or greater)

- *

- Please inquire about our ability to manufacture other sizes or for more detailed specifications.